As a garment quality control (QC) service provider, our main priority is to ensure that our clients’ products are manufactured to the highest possible standards. We achieve this by working closely with our clients and their suppliers to ensure that all QC procedures are followed and that any potential issues are identified and rectified before mass production begins.

In order to provide the best possible service, we have a team of highly experienced and qualified QC inspectors who are stationed at our clients’ factories to carry out regular inspections. Our inspectors have a wealth of knowledge and experience in the garment industry and are able to identify even the smallest of defects.

Once an inspection has been carried out, our team will compile a detailed report which will highlight any areas of concern. We will then work with our clients and their suppliers to rectify any issues that have been identified.

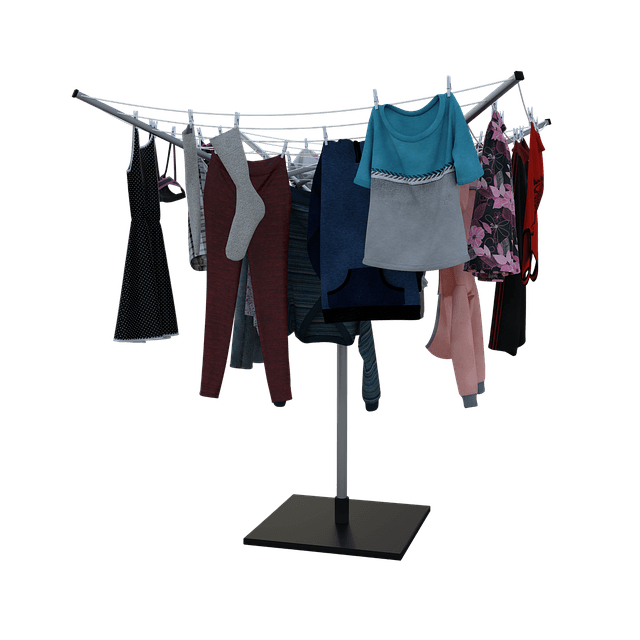

Visual check for defects according to AQL inspection requirements to check if the defect rate is within the allowed limits or not.

Our Services:

On-site Inspection

- AQL inspection requirements

Quality control – QC

- function test

- drop test

- rub test

- consumption test

- durability test

- wash test etc.

Pre-shipment inspection

- Initial Production Check

- During Production Check or During Production Inspection

- Final Random Inspection

- Container Loading Supervision

- Production Monitoring

- Random Product Sampling

- Factory Audit and Social Audit